NovoPacks gives Europe direct access to a production complex capable of meeting continental demand.

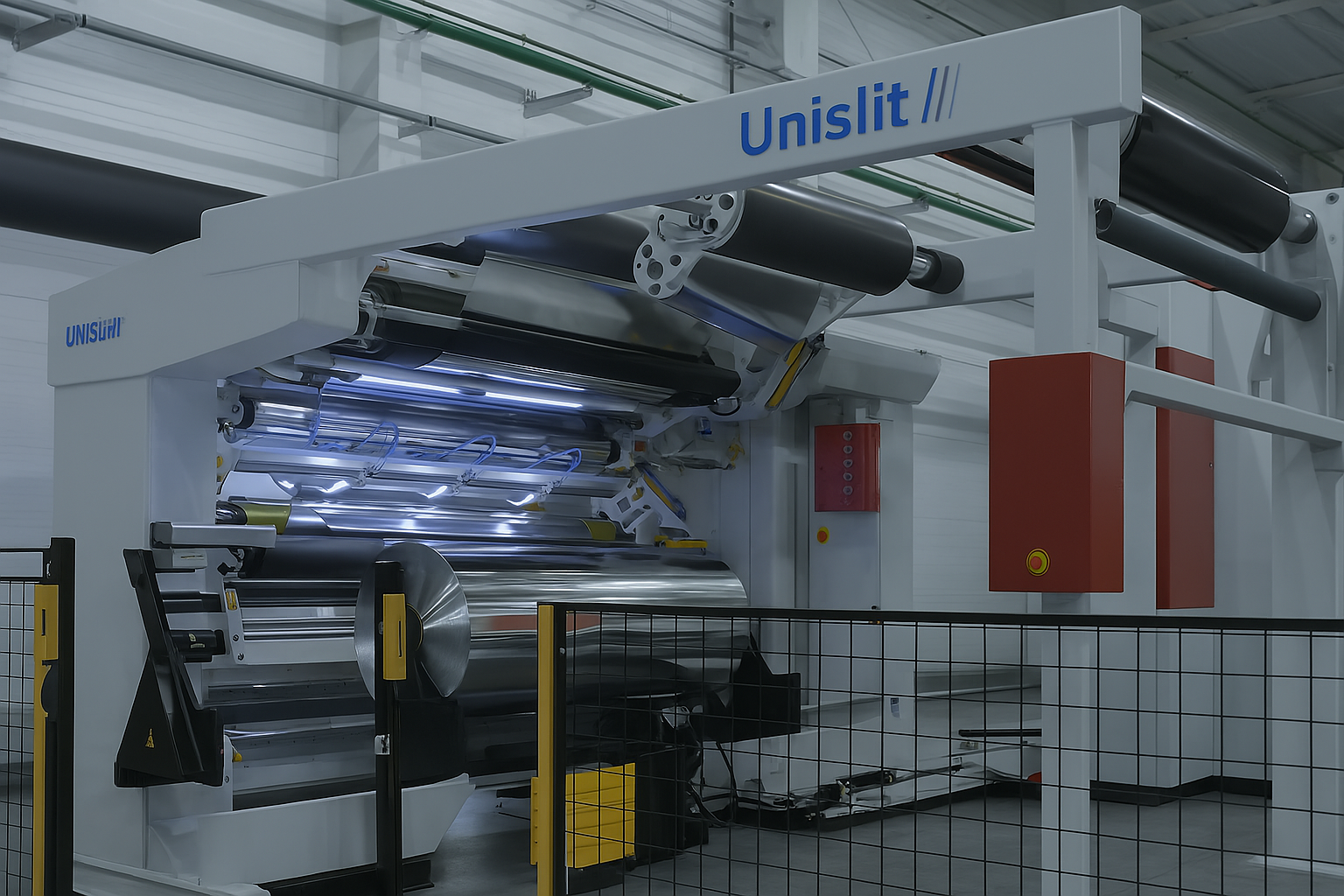

As the sole authorized distributor for Europe, we channel the output of an ISO‑run facility that operates a full polymer cycle—from yarn extrusion to finished film and fabric—on Starlinger and Lohia machinery.

Factory scale & output

-

36 million woven bags and soft containers per month (stitched sacks, block‑bottom bags, single‑/double‑/four‑loop FIBCs).

-

20 000 tons per year of stretch and shrink polyethylene film (cast and blown lines).

-

25 000 tons per year of BOPP packaging film in clear, pearl, matte and metallized grades.

These volumes power global supply chains and guarantee NovoPacks customers consistent stock, even during peak seasons.

Quality & compliance

All woven products conform to GOST 35522‑2013 workmanship criteria and EAEU TR CU 005/2011 packaging‑safety rules. Film grades designed for food or pharma are produced with resins and additives compliant with EU Regulation 10/2011. Every shipment includes certificates of conformity and full lot traceability.

Sustainability

BOPP, PE and PP articles are 100 % recyclable. Nano‑layer stretch films reduce plastic use by up to 40 % per pallet; optional formulations include 20–30 % post‑industrial PCR without loss of performance. UV‑stabilised fabrics extend outdoor life, minimising replacement cycles.

Logistics advantage

Imported and distributed through Varna, Bulgaria lets us combine mixed SKUs—stretch film today, FIBCs tomorrow— cutting lead times across the EU. Our technical team supports on‑site line trials, drop‑tests and pallet‑stability studies to lower waste and maximise throughput.

From stabilising appliance pallets to protecting agricultural harvests, NovoPacks translates world‑class production capacity into fast, reliable packaging supply for European agriculture, construction, logistics, food processing and retail.