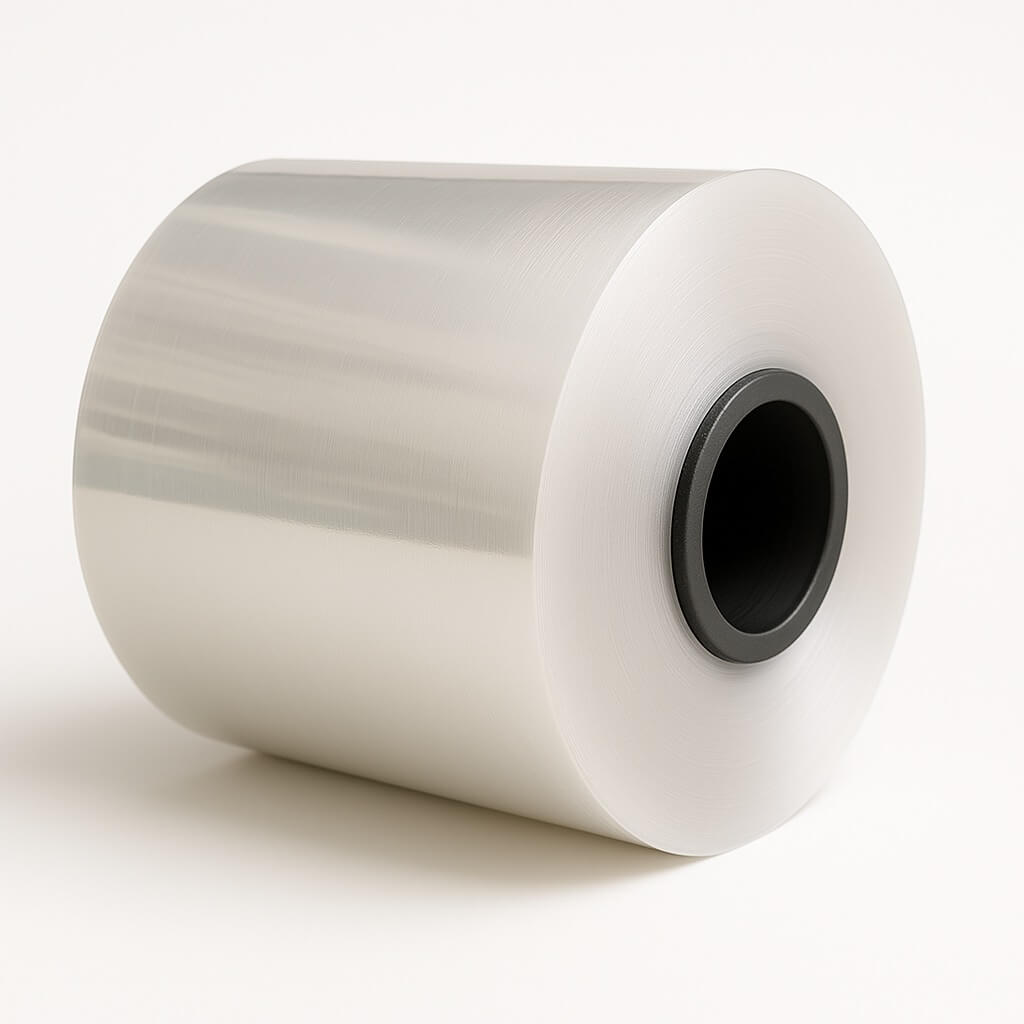

NovoPacks supplies premium biaxially oriented polypropylene (BOPP) films engineered for high‑speed packaging, lamination and label applications. Produced on state‑of‑the‑art tenter and simultaneous‑stretch lines, our films range from 15 µm to 60 µm and include transparent, pearlised, matte and metallised grades.

Food‑grade resins deliver superior gloss, stiffness and moisture‑vapour protection, while both sides can be corona‑ or acrylic‑treated for outstanding ink adhesion and cold‑seal performance. Whether you’re flow‑wrapping snacks, over‑laminating pouches, producing pressure‑sensitive labels or slitting tape, NovoPacks’ BOPP films provide the optical clarity, heat‑seal integrity and dimensional stability required for automated FFS and VFFS machinery.

All grades are recyclable, EU‑compliant and BPA‑free. Custom roll widths, core diameters and surface treatments are available, with just‑in‑time delivery across Europe from our Polish distribution centre.